The 3D printed packaging market is witnessing a surge of innovation, fueled by advancements in technology and evolving consumer demands. As the market is set to grow at a 7.6% CAGR from 2024 to 2030, innovation remains the cornerstone of this expansion.

Customization Like Never Before

One of the most significant advantages of 3D printing is its ability to cater to customization. Brands can design intricate packaging tailored to specific consumer needs, enhancing product appeal and brand identity. This is particularly beneficial in luxury goods and personalized product segments, where uniqueness is key.

Material Advancements

The development of new materials has revolutionized 3D printed packaging. From biodegradable polymers to food-grade materials, the range of options is expanding. These materials offer durability, flexibility, and eco-friendliness, meeting both industry requirements and consumer expectations.

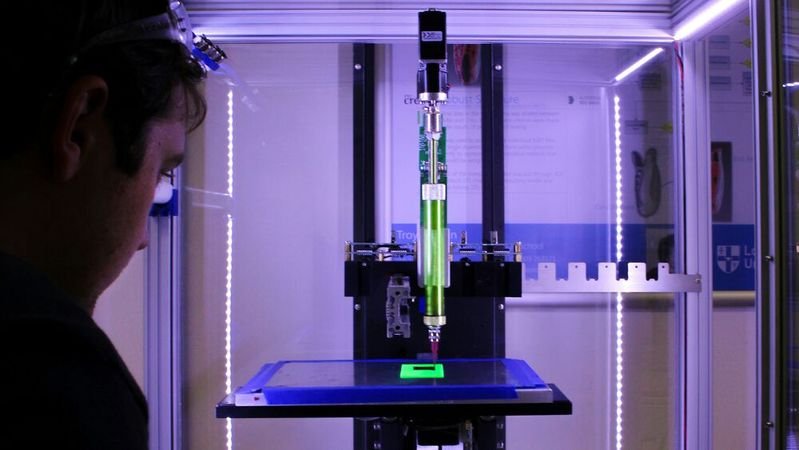

AI Integration in 3D Printing

Artificial intelligence is enhancing the efficiency and accuracy of 3D printing. By optimizing designs, predicting maintenance needs, and automating production processes, AI is making 3D printed packaging more accessible and cost-effective. This integration is particularly useful in reducing production times and errors, ensuring consistent quality.

Applications Across Industries

From food and beverages to healthcare, 3D printed packaging is finding applications across various sectors. Its ability to produce sterile and secure packaging has made it indispensable in the pharmaceutical industry. In the food sector, innovative designs ensure product freshness and consumer convenience.

Conclusion

The innovations in 3D printed packaging are not just reshaping the industry—they’re redefining the possibilities of packaging itself. With continued advancements, 3D printing is poised to become a dominant force in the packaging world.